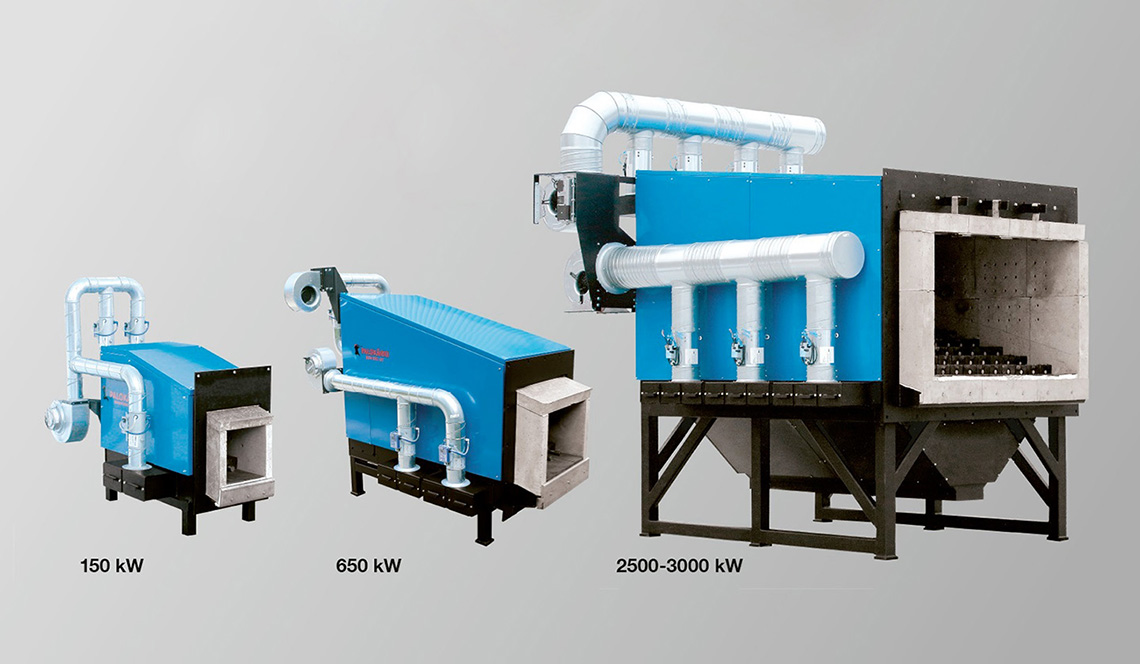

Palokärki burners 60-3000kW

In the Palokärki burners, the grate size has been dimensioned approx. 20% larger than the nominal power, and this ensures that the nominal power is also reached when burning fuel of a lower quality. Efficient burning is also performed by using a more humid fuel, because the grate is long and staggered, and this allows for the fuel pushed into the upper part of the grate from the rear edge of the burner to dry, before it is transferred into the actual combustion area.

- Due to the large grate, nominal power is obtained, even with a fuel of poorer quality.

- A long grate promotes the combustion of more humid fuel.

- A burner can also be used to burn other fuels, such as pellets, grain and the husk waste created when drying grain, as a mixture with wood chips and/or peat.

- Due to the steplessly adjustable flame, the system does not require an accumulator.

- The burner is able to operate on extremely low power (2–10% power)

- The burner can be equipped with an automatic ignition.

The fuel is pushed from the intermediate tank via the screw in the burner’s combustion end where combustion occurs. The design of the combustion end gasifies extremely well, due to a descending upper part, i.e., the roof, and the combustion air is forced to mix with the combustion gases. From the combustion end, the flame is led to the boiler’s convection.

A strong staggered cast-iron grate

A strong hydraulically moving grate aggregate

Massive ceramic side and roof stones

Precise air distribution and energy-efficient combustion-air fans

0* – the burner must be equipped with an automatic ignition, because, otherwise, the minimum power is approximately 2–10% of the nominal power. The minimum power is affected by, for example, chimney draught and the fuel used.