The Biofire pellet heating plants produce energy with a good efficiency, and using them for heating is affordable and effortless. The energy value of the pellet is big, so there is no need for a large fuel storage.

Due to the moving grate aggregate, even grain can be burned in Biofire’s Palokärki burners. At its best, the energy value of grain is nearly 90% of the energy value of pellets, so use of grain as fuel is sensible. Suitable grains for burning include, for example, low-price grains created during sorting.

- For agricultural heating needs

- For heating of properties

- Heating containers

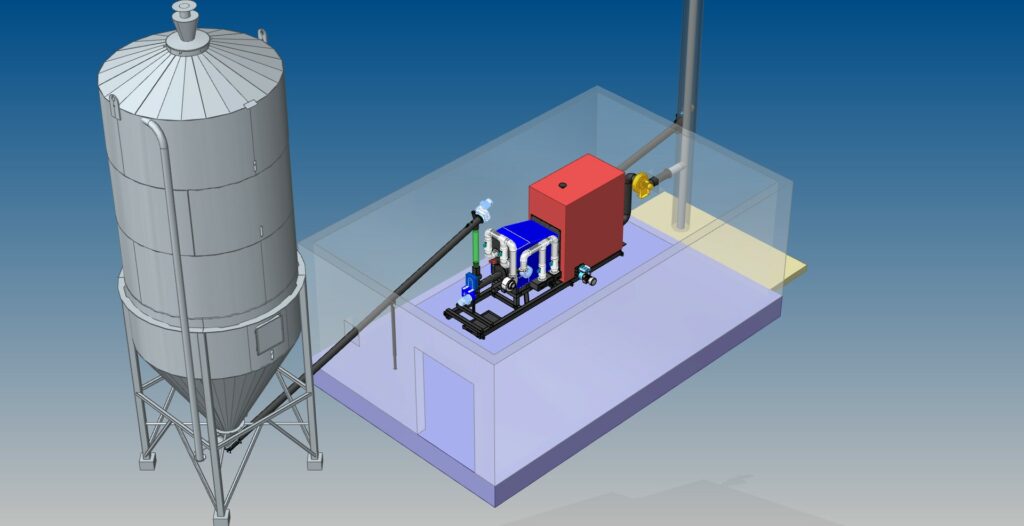

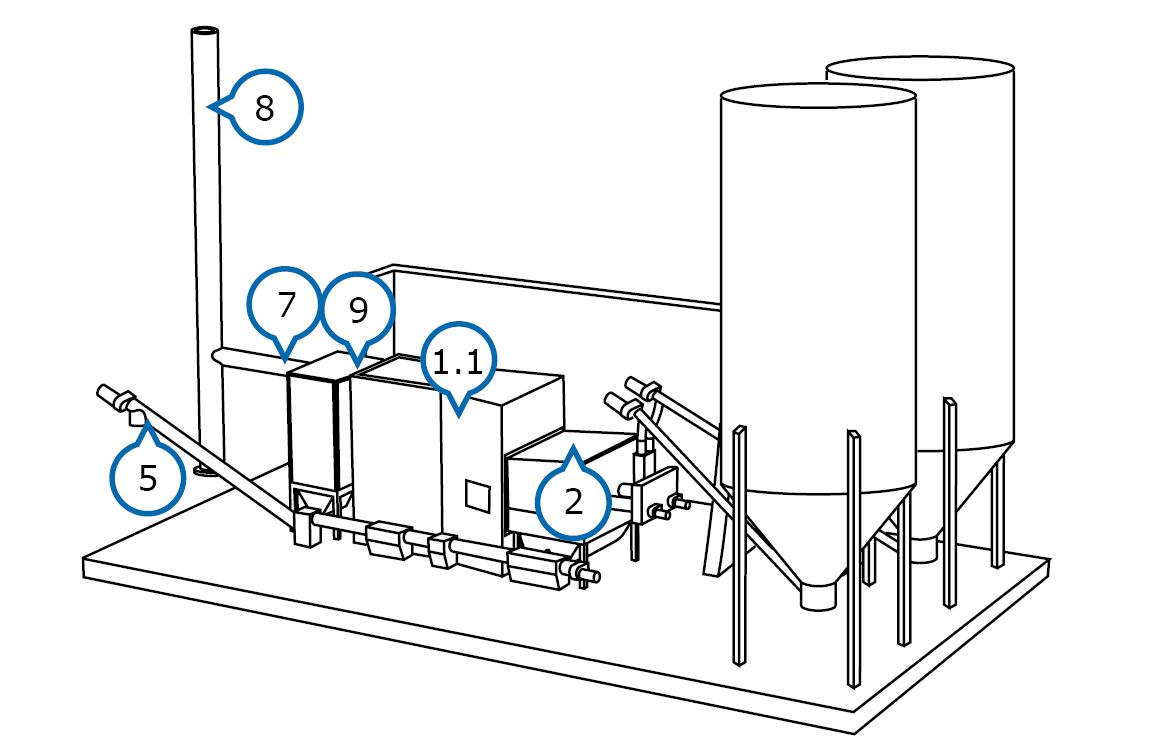

Heating-plant components and operational description

1.1 Boiler

2. Burner

3. Pellet feeder

4. Pellet silo

5. Ash removalremoval

6. Ash receptacle (not pictured)

7. Flue gas fan

8. Chimney

A system in accordance with EN303-5 standard. The fuel is stored in an appropriate silo from where it can be led to the feed hopper inside the boiler room via a screw conveyor. The level of the tank is measured by using a capacitive sensor. Fuel flows through the rotation valve via the feeder screws to the combustion end of the burner (2).

Burning occurs in the combustion end and the flame is conducted inside the boiler (1.1). The automation adjusts the burning steplessly. If needed, the fuel supply and combustion-air fans react quickly to the fluctuation of power requirements by increasing or decreasing the power. The combustion air is controlled, using precise air-flow regulators and LAMBDA measurement. The heat is transferred from the boiler’s convection surfaces to the boiler water, which is kept at a consistent temperature maintained by using the PT-100 measurement.

The burned out fuel is pushed out as ash into the boiler’s ash space with the help of the hydraulically moving grate aggregate. The ash is transported with screw conveyors (5) into a large ash receptacle (6) located outside the building.

The vacuum-controlled flue gas fan (7) keeps the boiler’s vacuum, i.e., draught, as desired, thus enabling the use of a wide power range.