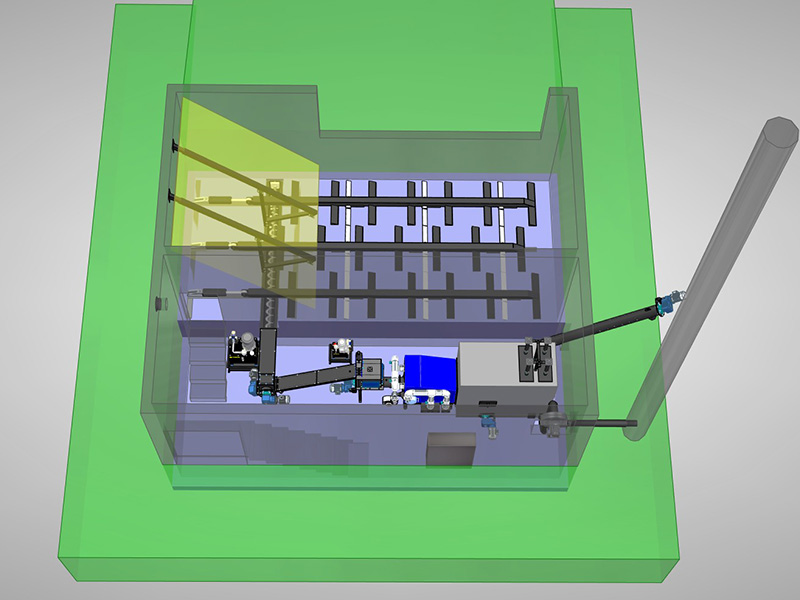

The pull bar storage is suited for applications where the heating plant requires a large fuel storage. The Biofire pushrod unloader storages allow a volume of up to 200 m3, which enables long refilling intervals.

- For agricultural heating needs

- For heating of properties

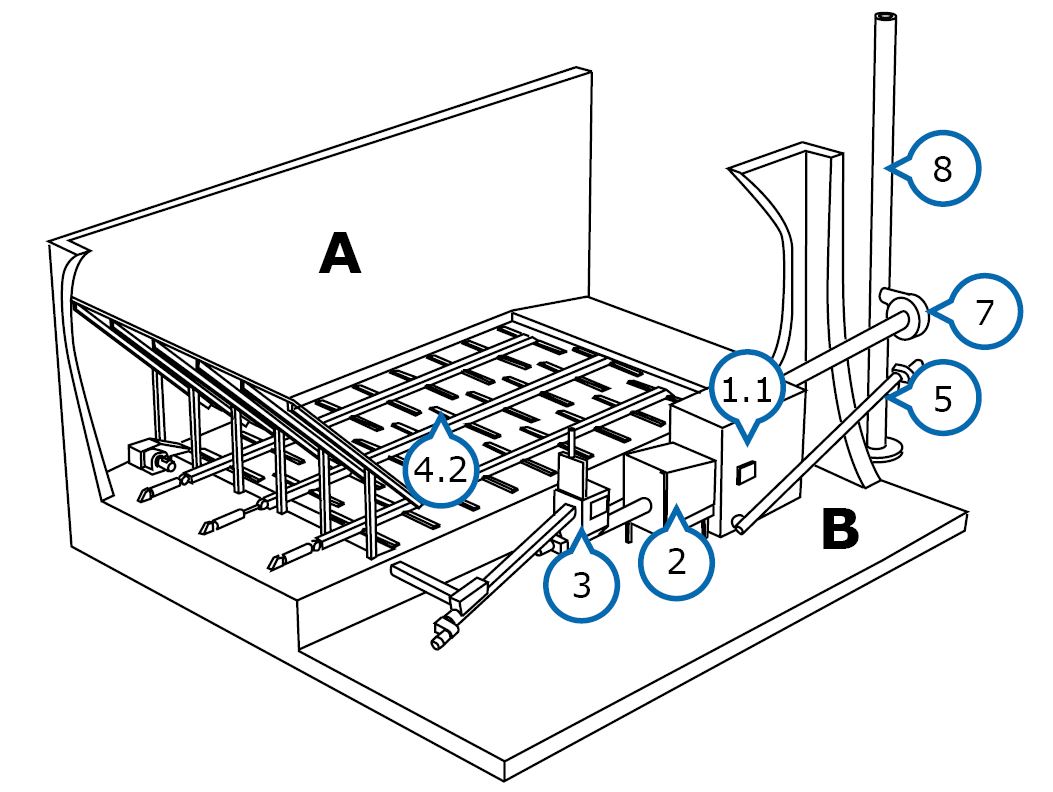

- Heating containers

A – Fuel storage

B – Boiler room

1.1 Boiler

2. Burner

3. Feed hopper

4. Pull bar feeder

5. Ash removal

6. Ash receptacle (not pictured)

7. Flue gas fan

8. Chimney

A system in accordance with EN303-5 standard. The sturdy and especially strong hydraulically operated pull bars (4.2) are placed on the floor of the fuel storage where anchoring irons have been installed during the concrete casting to reinforce the structure.

The bars pull the fuel to the transverse conveyor screw at the rear section of the storage. The lifting trough-conveyor transports the fuel to an feed hopper (3), which is equipped with a hydraulically operated closing hatch. The level of the feed hopper is monitored, using an ultrasound sensor.

The fuel is fed from the feedhopper, using a screw conveyor, to the combustion end of the burner (2). Burning occurs in the combustion end and the flame is conducted inside the boiler. The automation adjusts the burning steplessly. If needed, the fuel supply and combustion-air fans react quickly to the fluctuation of power requirements by increasing or decreasing the power. The combustion air is controlled, using precise air-flow regulators and LAMBDA measurement. The heat is transferred from the boiler’s convection surfaces to the boiler water, which is kept at a consistent temperature maintained by using the PT-100 measurement.

The burned out fuel is pushed out as ash into the boiler’s ash space with the help of the hydraulically moving grate aggregate. The ash is transported with screw conveyors (5) into a large ash receptacle (6) located outside the building.

The vacuum-controlled flue gas fan (7) keeps the boiler’s vacuum, i.e., draught, as desired, thus enabling the use of a wide power range.