A chip storage’s bottom discharger equipped with hydraulic pushrod unloaders

The robust, bottom discharger made of steel is a reliable discharge system for fuel storage. The bottom discharger functions well with wood chips, peat, and other fuels and fuel mixtures alike. Strong hydraulically operated discharge rods will move the fuel efficiently, taking it to an uncloggable U-shaped conveyor screw which transports the fuel to the intermediate tank for dosage.

To monitor rod movement, the control system uses a pressure transmitter for determining the optimal movement path for the rods. Due to their bottom reinforcement, the rods are extremely sturdy. The discharger edges have been tilted at a suitable angle, so that the fuel has space to move from the edges up, without becoming packed.

The bottom discharger can also be utilised in other transfer and feed requirements of solid materials (such as in the packing of cutter chips).

The robust-structured Palokärki feeder operates reliably

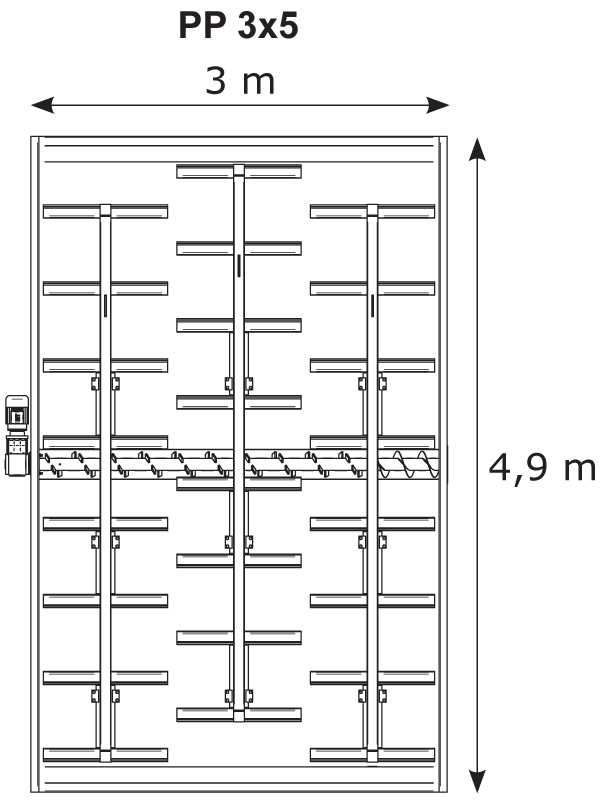

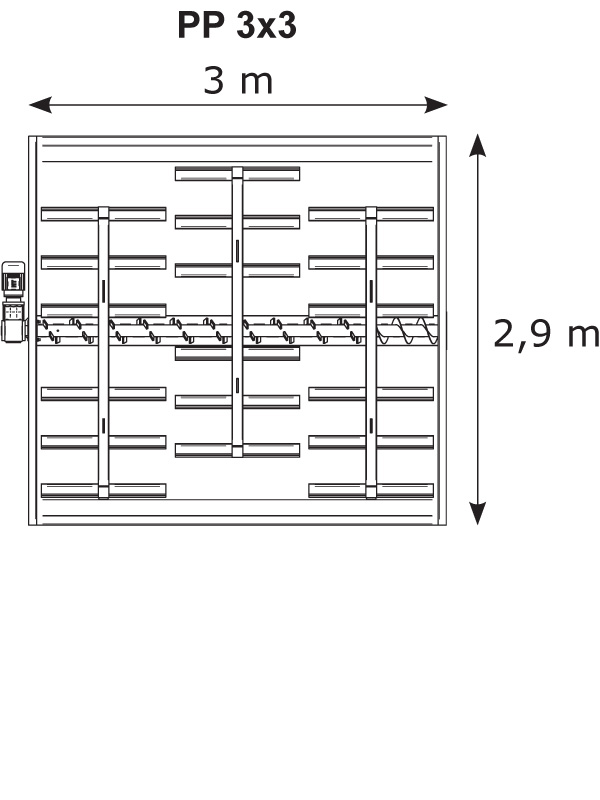

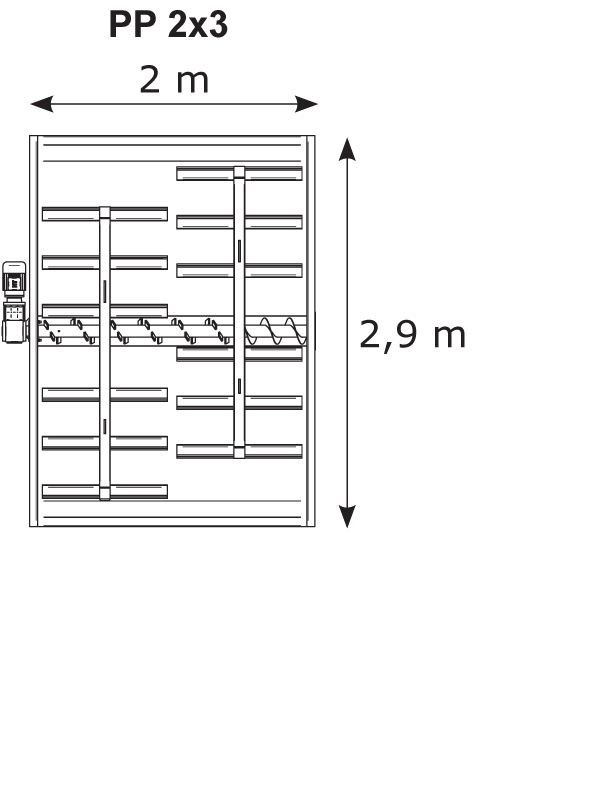

Bottom discharger dimensions:

* Ø 270 mm conveyor screw only by special order